Product

Introduction

Contact

| Name: | Shanghai whisker composites Manufacturing Co., Ltd. |

| Add: | Mrs Law No. 591 Road, Baoshan District, Shanghai |

| Contact: | Mr. Ji |

| Tel: | 86-21-66866132 |

| Fax: | 86-21-66866136 |

| Email: | 13764556038@163.com 13816965761@126.com |

Introduction

Home>> IntroductionSix potassium titanate whisker

Penster : Source : Date : 2014-01-03The brief introduction of potassium hexatitanates

The chemical formula of potassium hexatitanates is K2O•6TiO2 or K2Ti6O13。

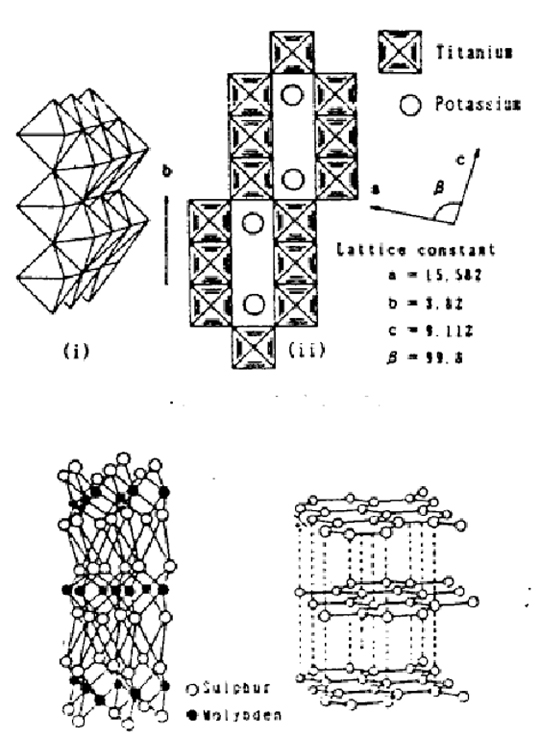

The crystal structures of potassium hexatitanates belong to monoclinic systems, point group is C2/m. In crystal structure of potassium octatitanates, the coordination numbers were 6, the tunnel form structure connected by TiO6 octahedron altogether angle and edge, K+ ions in the middle of tunnel, axis of tunnel and crystal axis were parallel, the figure of crystal structure as follow:

The figure of crystal structure of potassium hexatitanates

The figure of crystal structure of potassium hexatitanates showed that K+ ions enclosed by structures with tunnel form so that they were divided from surroundings, which made K+ ions couldn't break through these tunnel layer and that chemical inertness.

The potassium hexatitanates had peculiar properties because of the chemical inertness on the structure of K+ ions.

1. The fine chemical inertness

Found expression in absorbing moisture, usually, the potassium hexatitanates don't react with acid, alkali and salt, and also don't blend with organic solvent.

2. The fine mechanical properties

The potassium hexatitanates were mainly used for reinforcing material of plastics, light metals and so on. Substitution of potassium hexatitanates crystal whisker for fiber-glass made thermoplasticity FRC on the premise of properties similar, which got over shortcomings of GFRC:the fabricated parts metamorphism easily after ingot stripping; The surface of fabricated parts was coarse; For the fabricated parts of precision moulding or complicated shape, by the fluidities of resin and fiber-glass were different, in some parts such as the end and so on would appear few fibers areas ; If having joint, the rigidity of the joint and around were evidently different; forming mechanism and mould seriously damaged. Used potassium hexatitanates to substitute traditional asbestos as friction materials, the friction coefficient was hardly change with the temperature, which had overcome the friction coefficient of asbestos fibers product to increase evidently, and that brought the phenomenon of "died".

3. The excellent heat shidleing performance

The coefficient of thermal conductivity of potassium hexatitanates crystal whiskers was small, it was 0.054 W/M•K at room temperature,at 800℃just was 0.017W/M•K,that was, potassium hexatitanates crystal whiskers had negative temperature factor. compared with traditional asbestos thermal insulation materials, the potassium hexatitanates crystal whiskers had salient features as follows: no poison and the properties were stable; the application temperature was high, that reaches up to 1000℃; longevity of service;didn't occur "cineration" phenomena and didn't pollute the environment and so on. The substitute to traditional asbestos materials, whether properties or cost, potassium hexatitanates crystal whiskers or rather the ideal materials.

4. The properties of high infrared reflection and sound – absorbent at high temperature

In fact, the high infrared reflection property of potassium hexatitanates crystal whiskers was one of the major reasons as thermal insulation materials.

5. The fine compatibilities

The compatibility with inorganic or organic matters was superfine, hardly existed interface reaction,and under the most of circumstances didn't need surface treatment, which increased the range of use.

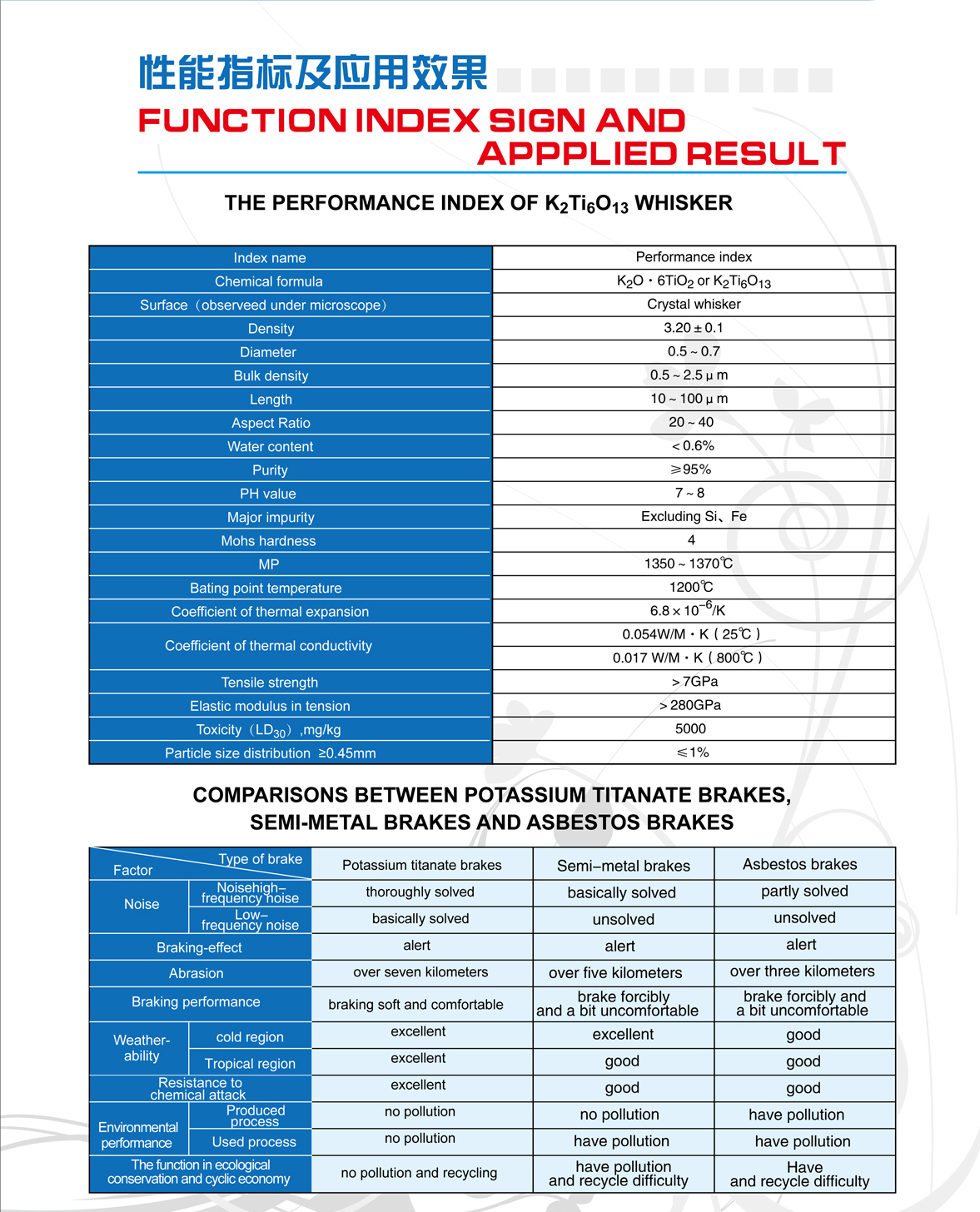

The major index of potassium hexatitanates crystal whiskers manufactured Shanghai Jingxu composite manufacturing CO., Ltd as follow:

| name | index |

| surface | acicular crystals |

| absolute specific gravity | 3.2±0.1 |

| bulk density | 0.4~0.8 |

| Water content(wt%) | ≤0.3 |

| Mohs hardness | 4 |

摩擦材料

Function index sign and appplied result

The purpose diagram of potassium titanate reinforced plastics

| Name | Instance of use |

| POM(polyformaldehyde) | Tooth wheel for clock, tooth wheel for camera, subminiature tooth wheel, tooth wheel drapertype recorder |

| PBT (polybutylene terephthalate) | Mechanical products, electric relay, cam, bolt, key switch, linker and so on |

| nylon-66 | Bearing, tooth wheel, cam, coil rotor, bearing guard ring and so on |

| nylon-6 | Bearing, tooth wheel, industrial zipper, ticket, pushbutton, industrial valve、coil framework and so on |

| Special nylon | Slip products, sound deadening tooth wheel, film products, mechanical part, gymnastic products and so on |

| Denaturating PPE | Platen machine products, FDD products , typewriter products, thin washer and so on |

| PPS | Platen machine products, slip parts, automobile products and so on |

| ABS | Platen machine, clock products, electroplated products, gymnastic products and so on |

| PVC | Bed for pearl, cladding tube, cummerbund and so on |

| PP | Phonic products, vacuum forming products, automobile products and so on |

高温保温材料

上海晶须复合材料制造有限公司多年来一直致力于高品质的高温保温材料的开发与应用,目前由其研制的JX复合高温保温材料,为用户解决了世界性的隔热难题。

JX复合高温保温材料是一种新型隔热保温材料,具有非常好的隔热性能和耐高温性,防腐蚀性等功能。常用于组建高温作业下的工业炉、热场,能大大有效地起到保温效果,阻绝热量流失,因此可起到简化加热工艺,降低反应堆所需的功率,稳定反应温度,减少能源消耗,持续节能的效果。

JX复合高温保温材料采用钛酸钾晶须发泡后与耐高温材料复合制作基料,在1450℃温度下定型制成。产品利用了钛酸钾晶须优良的红外线反射率,使制作出的产品具有良好的储热功能,从而达到高效的隔热保温功能。

JX复合高温保温材料颠覆了传统保温材料的保温原理。通过发泡钛酸钾晶须储存热量,当炉内温度降低时释放热量,来达到长时间的均恒保温,可谓是高温保温领域的一次革命。

由于JX复合高温保温材料的热储藏能力,使炉子所需的加热功率和加热时间明显降低,从而达到节能百分之三十左右的效果。

经过上海晶须复合材料制造有限公司大量的实验研发,产品现在可分为三种:一、耐高温1790℃,导热系数 0.316W/(m•k);二、耐高温1650℃,导热系数0.250W/(m•k);三、耐高温1650℃,导热系数0.250W/(m•k)。

目前,这种保温材料已应用在多元化单晶硅生产炉的保温层中。出于节能角度考虑,建议可将保温层分为三层。第一层保温砖红外线反射达到数值63.9,并能耐1790℃的高温,导热系数 0.316W/(m•k);第二层保温砖红外线反射59,耐火度1650℃,导热系数0.250W/(m•k);第三层保温砖红外线反射54,耐火度1330℃,导热系数0.247 W/(m•k)。这样既节约成本,又能起到预期节能效果。由于JX复合高温保温材料制造的保温砖具有良好的抗折3.2MPa和耐压强度16.6MPa,可以将其运用在大型炉内。

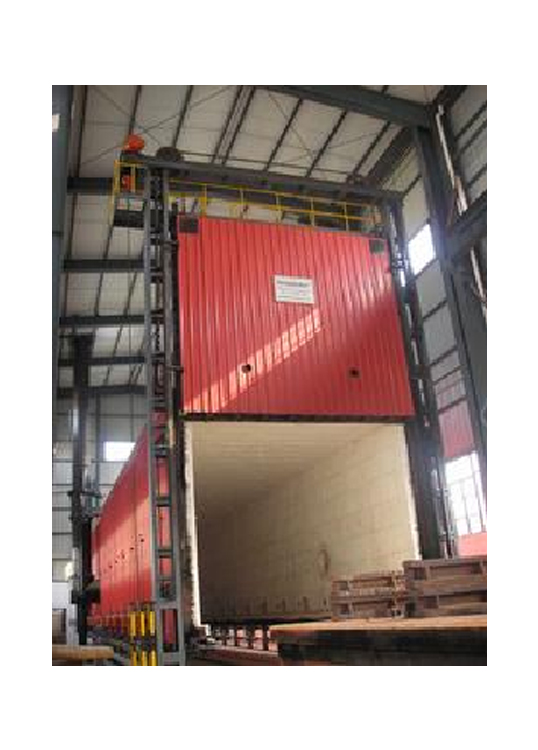

隧道窑

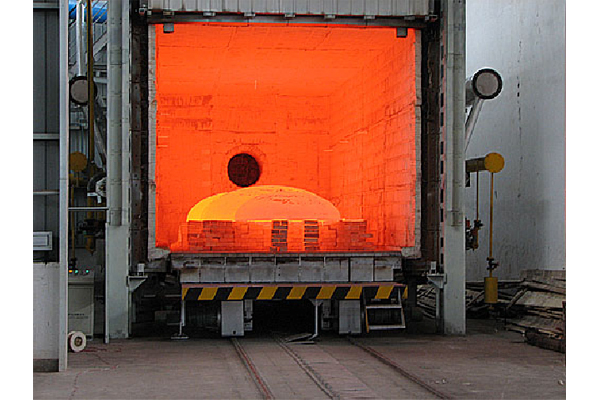

工业电炉

燃气工业炉

燃气工业炉

欢迎国内各行业的客户和专家与我们联系,合作推广这种新型节能隔热材料,为我国的节能降耗和可持续发展,以及由此导致的低碳排放工程作出应有的贡献!

JX复合高温保温材料(砖)特点

一、 红外线储热功能。

二、 耐火度高(1800℃)。

三、 导热系数低,0.3左右。

四、 抗压强度好。

五、 折弯强度好。

六、 防腐蚀功能。

六 钛 酸 钾 晶 须 涂 料

1. 涂料对六钛酸钾晶须的要求

作为涂料的填料,因为涂层一般只有数十微米厚,因此,要求填料的粒度不能太大。六钛酸钾晶须本身的长度在30μm左右,直接使用会使涂层表面不平整。为此,上海晶须复合材料制造有限公司使用机械方法,将六钛酸钾晶须加工成粒度为1~3μm的颗粒,便于在各种涂料中使用。

2. 六钛酸钾晶须在涂料中的作用

(1)提高涂层的硬度,不改变原涂料的表面丰满度;

(2)提高涂层的耐磨性能;

(3)提高涂层的耐热温度,扩大了涂料的使用范围;钛酸钾材料的加入,对涂层起阻燃作用,提高了安全性;

(4)由于六钛酸钾本身的高红外线反射率和优良的化学稳定性,使涂层与环境的温差变小,特别是在有阳光照射和热能传递的区域,部分能量反射,减小了阳光辐射或热能传递给涂层引起的色差,从而延长了涂层的使用寿命;

(5)六钛酸钾本身不吸收微波和射线,甚至在核辐射条件下,也不会被破坏,可以作抗辐射(包括核辐射)涂料的填料;

(6)与大部分有机和无机黏合剂的相容性好,无需进行表面处理即可作为填料使用。

3. 应用简述

钛酸钾晶须的使用情况列于下表中

| 名称 | 用途 | 备注 |

| 特种高温防腐涂料 | 使用温度500℃以下,钛酸钾增强有机硅涂料,主要用于化工设备等的涂层防腐。 | 上海晶须复合材料制造有限公司开发成功 |

| 隔热涂料 | 使用温度300℃以下,涂层厚度约3㎜,主要用于化工管道等的隔热保温。 | 上海晶须复合材料制造有限公司开发成功 |

| 金属涂料 | 1000℃高温涂料 | 上海晶须复合材料制造有限公司开发研制 |

| 陶瓷涂料 | 化工容器表面防腐涂料 | 上海晶须复合材料制造有限公司开发研制 |

| 抗核辐射涂料 | 主要用于核电厂厂房、有核辐射材料的库房等 | 上海晶须复合材料制造有限公司开发研制 |

| 防火涂料 | 主要用于化工材料的防火保护涂层 | 尚在开发中 |

| 耐火涂料 | 主要用于高温容器表面 | 尚在开发中 |

| 水性涂料 | 5%添加,可将2H硬度提高到4H,主要是家具饰面涂料 | 青上海晶须复合材料制造有限公司开发成功 |

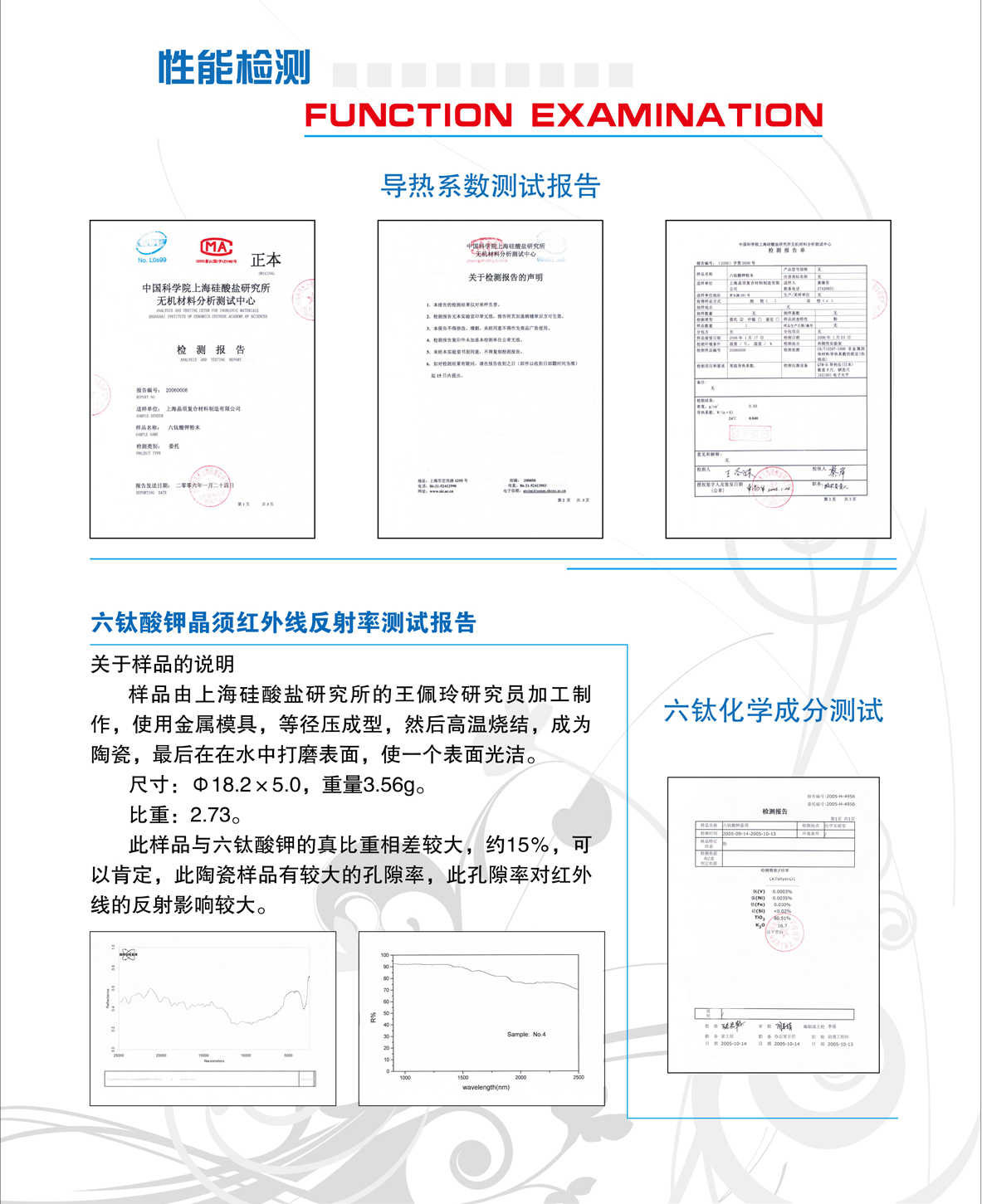

性能检测